Launching and receiving pipeline pigs using commonly found barrel senders and receivers can be a dangerous job, particularly if not done with safety in mind. Pipetech is focused on helping our customers do their jobs safely and effectively using best practice procedures.

There are several hazards that must be identified and taken into account prior to opening a barrel sender or receiver. This is particularly important when working with gas systems.

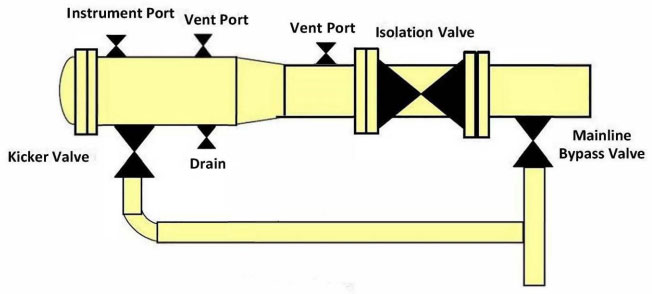

As our industry is prone to using slang terms to describe things commonly found in the oilfield, we will use drawings to identify the various parts of a typical barrel. Note: These are basic illustrations for reference purposes only. Your piping system may differ, and should be looked at individually.

Launching

The main items we are concerned with on the launcher are the drain valve, vent valves on the oversize portion of the barrel and also on the nominal section of the barrel, as well as the positioning of the isolation valve, bypass valve and kicker valve. Operation of any valve should be done slowly and in a controlled manner! Not all barrels have two vent valves. If you have two valves as shown above, USE THEM BOTH.

Prior to opening the drain or vent valves you must ensure that the by-pass valve is open and the isolation and kicker valves are closed. This would be considered an “isolated” barrel. Slowly open the vent on the oversize portion of the barrel, then slowly open the vent on the nominal portion of the barrel. This will vent gas inside the barrel to remove the pressure. It is a redundant safety function to use both vents to limit the possibility of a vent becoming plugged with debris or icing off while venting. Once the gas has vented, slowly open the drain ensuring that there is proper containment below the drain valve to catch any fluids that are in the barrel.

With the drain and both vents fully open and no audible sound of gas venting or fluids draining, check the pressure gauge on the instrument port (if available) and ensure that the gauge also shows no pressure. Provided all of these items show no indication of pressure present you are now able to open the barrel closure (door).

Ensure there is proper containment below the closure prior to opening it. When opening a barrel NEVER STAND DIRECTLY IN FRONT OF THE CLOSURE! Stand to the side of the closure that the door swings away from. Open the barrel closure, using the proper wrench to loosen it and avoid the use of a hammer as striking the closure lugs can cause stress fracturing that can lead to a closure failure. Once the closure is loosened, slowly unthread the closure while continuously wiggling the closure. This is a good practice that is also a safety habit to ensure there is no pressure in the barrel in the event that your previous checks failed. Once the closure is fully opened use a mirror to look inside the barrel and ensure there are no obstructions inside the barrel. NEVER PUT YOUR HEAD DIRECTLY IN FRONT OF THE BARREL TO LOOK INSIDE! This would be like looking down the barrel of a gun, it’s something you should never do. If the barrel is clear you can insert the pig. Push the pig as far as possible into the nominal section of the barrel to “seat” the pig. This will help to get the pig to launch without production flowing around the pig.

Clean the O-ring and the threads of the closure and barrel with a rag, inspect the threads and O-ring for any physical damage/distortion. If you have a thread inspection tool from the closure manufacturer this would be the best way to check the threads. Lubricate the closure threads and O-ring with the appropriate grease as recommended by the closure manufacturer. Spin the door closed by hand. The door should thread on with minimal effort, if it does not, recheck threads for damage or dirt in the threads. Using the proper wrench, it should only take a slight “knocking” effort to tighten the barrel closure fully and ensure a proper seal. If you need to hammer on the lugs to get the door to seal then there is something wrong such as a flattened O-ring or stretched threads and should be noted/reported for maintenance.

Now that the pig is in place and the barrel closed, all of the vents and the drain can be closed. Leaving the isolation valve closed, slowly open the kicker valve to “equalize” the barrel. You may hear or feel a thud/thunk as the pig will likely move further into the nominal section. Once there is no longer any audible sound or vibration of the barrel filling, slowly close the kicker valve. You can now fully open the isolation valve. Do not open the isolation valve while production can flow through the barrel or you could cause damage and undue stress on the isolation valve and you will cause damage to the pig. It would be kind of like driving your truck into the garage while the door is opening…You’re going to wreck something. When you have the isolation valve fully open, re-open the kicker and slowly close the by-pass valve. This will direct all flow through the barrel and launch the pig into the line. Most cup/disc and brush pigs are easy to hear when they leave the barrel. A soft pig or a cup only pig is more difficult to hear. You can place your ear against the riser pipe to listen for the pig moving through the line. Depending on your companies protocol you may leave the line with production flowing through the barrel OR you may need to re-open the by-pass line and close the isolation and kick valves to isolate the barrel. This is dependent on your specific pipeline operating manual procedures.

Receiving

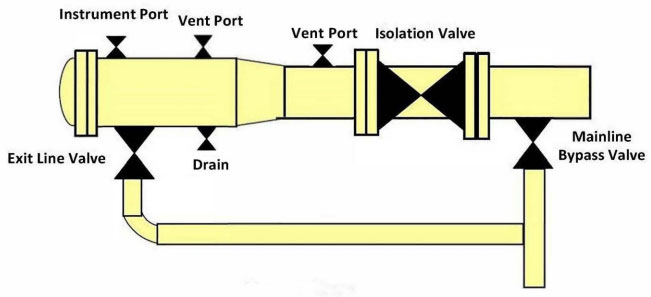

Again, we will use a drawing to identify the various parts of a typical barrel. Please note: these are basic illustrations for reference purposes only. Your piping system may differ and should be looked at individually.

Receiving a pig is much more dangerous that launching a pig. This is because you will have the pig (a potential projectile) as well as debris that the pig brought in to the barrel present inside the barrel.

As with launching the pig the main items we are concerned with on the receiver are the drain valve, vent valves on the oversize portion of the barrel and also on the nominal section of the barrel, as well as the positioning of the isolation valve, by-pass valve and exit valve. Operation of any valve should be done slowly and in a controlled manner! Not all barrels have two vent valves. If you have two valves as shown above, USE THEM BOTH. This is critical on the receiver to ensure your safety!

Some companies will flow fully through the receiver, others may leave the by-pass open and also have the isolation valve and exit line open during pigging. If you leave the by-pass open during pigging this can cause the pig to stop just past the by-pass line and not come fully into the barrel as flow will simply go down the by-pass line and stop pushing the pig into the barrel. Depending on your piping configuration, the pig could sit in the isolation valve or in the nominal section of the barrel. Both scenarios are potentially dangerous to the operator and/or damaging to equipment. If this is the case for your company please remember the following caution.

Prior to doing anything else, it is best practice to flow through the barrel fully to sweep potential solids from the nominal section of the barrel and to also ensure the pig did not stop in the nominal section and remain in seal.

When flowing fully through the barrel, the pig should come up to the exit line before it stops.

Prior to opening the drain or vent valves you must ensure that the by-pass valve is open and the isolation and exit valves are closed. This would be considered an “isolated” barrel. Slowly open the vent on the oversize portion of the barrel, then slowly open the vent on the nominal portion of the barrel, this is particularly important on the receive to ensure there is no pressure behind the pig. Pressure can be held behind a pig in a receiver for a number of reasons including a mud plug or a hydrate. This will vent gas inside the barrel to remove the pressure. It is a redundant safety function to use both vents to limit the possibility of a vent becoming plugged with debris or icing off while venting. Once the gas has vented, slowly open the drain ensuring that there is proper containment below the drain valve to catch any fluids that are in the barrel. With the drain and both vents fully open and no audible sound of gas venting or fluids draining, check the pressure gauge on the instrument port (if available) and ensure that the gauge also shows no pressure. Provided all of these items show no indication of pressure present you are now able to open the barrel closure (door).

Ensure there is proper containment below the closure prior to opening it. When opening a barrel NEVER STAND DIRECTLY IN FRONT OF THE CLOSURE! Stand to the side of the closure that the door swings away from. Open the barrel closure, using the proper wrench to loosen it and avoid the use of a hammer as striking the closure lugs can cause stress fracturing that can lead to a closure failure. Once the closure is loosened, slowly unthread the closure while continuously wiggling the closure. This is a good practice that is also a safety habit to ensure there is no pressure in the barrel in the event that your previous checks failed. Once the closure is fully opened use a mirror to look inside the barrel and ensure there are no obstructions inside the barrel. NEVER PUT YOUR HEAD DIRECTLY IN FRONT OF THE BARREL TO LOOK INSIDE! This would be like looking down the barrel of a gun, it’s something you should never do. If the barrel is clear you can remove the pig. If the barrel is not clear, extreme caution should be used to pull the pig from the barrel as debris can hold pressure behind it. If this were the case, dislodging the debris can cause a rapid release of pressure which could cause injury or death. You may try closing the barrel again and flowing through the barrel to clear it. Repeat the barrel isolation procedure and check if the debris has cleared. If it has not cleared, all efforts to ensure the barrel is vented should be done prior to attempting pig retrieval.

Clean the threads and the O-ring of the closure and barrel with a rag, inspect the threads and O-ring for any physical damage/distortion. If you have a thread inspection tool from the closure manufacturer this would be the best way to check the threads. Lubricate the closure threads and O-ring with the appropriate grease as recommended by the closure manufacturer. Spin the door closed by hand. The door should thread on with minimal effort, if it does not, recheck threads for damage or dirt in the threads. Using the proper wrench, it should only take a slight knocking effort to tighten the barrel closure fully and ensure a proper seal. If you need to hammer on the lugs to get the door to seal then there is something wrong such as a flattened O-ring or stretched threads and should be noted/reported for maintenance.

Now that the pig has been safely removed and the barrel closed, all of the vents and the drain can be closed. Depending on your companies protocol you may leave the line with the barrel isolated OR you may need to reopen the exit and isolation valves to allow flow through the barrel. This is dependent on your specific pipeline operating manual procedures.

Don’t be complacent, take the extra time to be diligent to identify and understand the hazards you are working around and how to safely deal with them. Use ALL safety measures available to you in your daily work and don’t take shortcuts.

Following best practice procedures and being safety conscious can save your life! At the end of the day we want everyone to go home safely to their families.